The ground wire is a critical component of the electrical system in your home or business. It is often overlooked, but it serves an essential purpose in keeping you and your property safe from electrical hazards. In this article, we’ll discuss why the ground wire is important and how it works.

In this blog, we will explore some of the common electrical problems associated with aluminum wiring.

- Oxidation and Corrosion Aluminum wiring is prone to oxidation and corrosion. This is because aluminum reacts with the oxygen in the air to form a layer of aluminum oxide on its surface. While this layer is generally non-conductive, it can lead to a buildup of heat at the connection points. Over time, this heat can cause the aluminum to corrode, leading to loose connections and even electrical fires.

- Thermal Expansion and Contraction Another issue with aluminum wiring is its tendency to expand and contract with temperature changes. When aluminum wiring is heated, it expands, and when it cools, it contracts. This can cause the connections to become loose over time, leading to increased resistance and heat buildup. If left unchecked, this can cause the wires to overheat, leading to electrical fires.

- Compatibility Issues Aluminum wiring is not compatible with all electrical components, particularly those designed for use with copper wiring. This can lead to issues with connections, such as loose fittings, arcing, and overheating. To avoid these problems, it is important to use connectors and devices specifically designed for use with aluminum wiring.

- Improper Installation is a common problem with aluminum wiring. The wiring must be installed correctly, with the proper connectors and devices, to ensure safe and reliable electrical connections. Poor installation practices, such as using improper connectors or not properly tightening connections, can lead to loose connections and electrical fires.

- Overloading Aluminum wiring is not as conductive as copper wiring, which means that it can carry less electrical current. Overloading the wiring with too much electrical current can cause the wires to overheat, leading to potential electrical fires. It is important to ensure that the electrical system is properly designed and installed to avoid overloading the wiring.

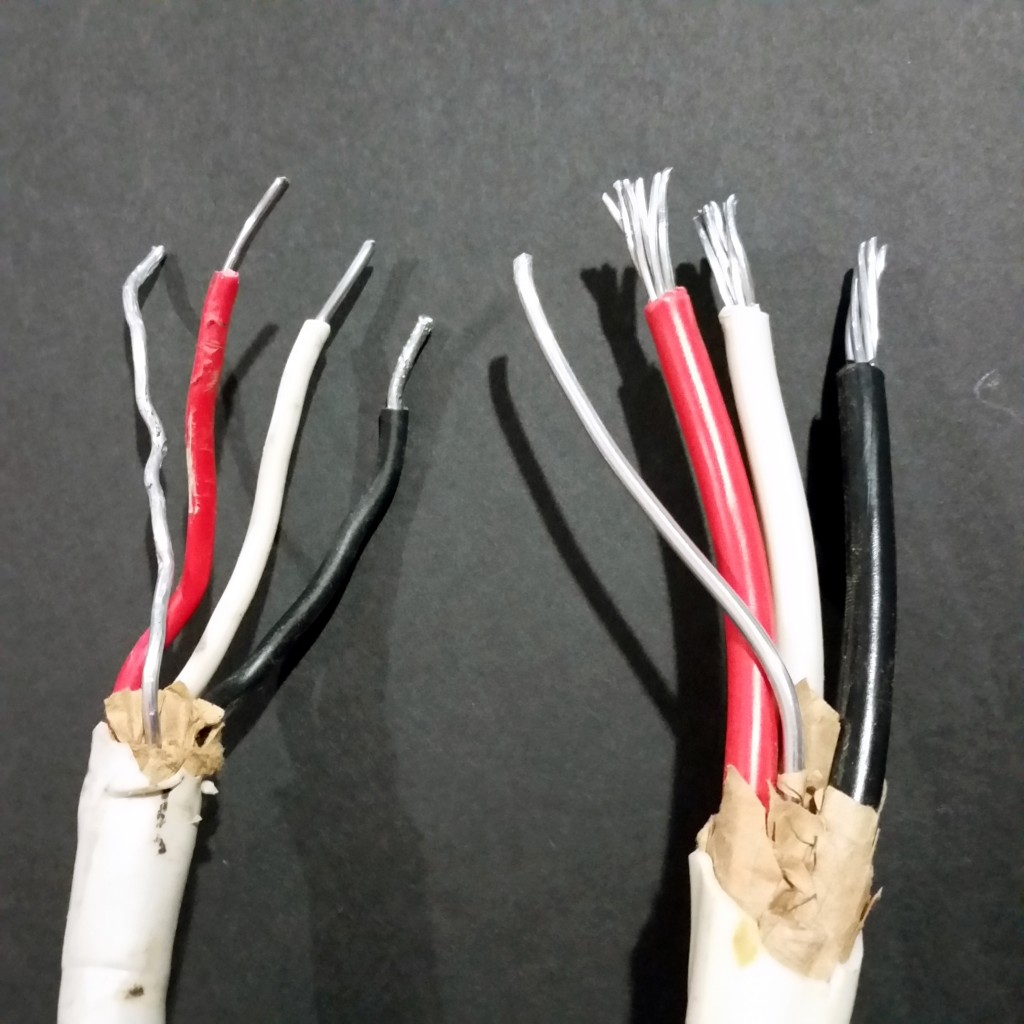

- Aluminum and Copper Connections When aluminum wiring is connected to copper wiring, it can lead to galvanic corrosion, which is caused by a chemical reaction between the two metals. Over time, this corrosion can cause loose connections and increased resistance, leading to heat buildup and electrical fires. It is important to use connectors specifically designed for use with both aluminum and copper wiring to avoid this issue.

- Age Finally, age is a common problem with aluminum wiring. As the wiring ages, it can become brittle and prone to cracking. This can cause the wires to break or become disconnected, leading to electrical fires. It is important to have the electrical system inspected regularly to ensure that the wiring is in good condition.

In conclusion, aluminum wiring can be problematic due to its tendency to corrode, expand and contract with temperature changes, and create loose connections. It is important to use connectors and devices specifically designed for use with aluminum wiring and to ensure that the wiring is installed correctly and not overloaded. Regular inspections can help to identify potential issues and prevent electrical fires. If you have aluminum wiring in your home, it is recommended to consult with a licensed electrician for a safety inspection.

Leave a Reply